Developing tomorrow's machines faster

In challenging times, it is crucial for machine builders to continue innovating and developing new competitive advantages. Lenze wants to be a partner in this endeavour. With the technology solutions from this German automation specialist, machine builders can sustainably increase their productivity and efficiency, even without in-house IT expertise.

The industry has dubbed it VUCA, referring to the challenging conditions and unimaginable dynamics that machine builders face today. It stands for volatility, uncertainty, complexity and ambiguity. “Four key words that characterise the impact of globalisation, the technological revolution and rapidly changing customer demand, especially in today's difficult economic climate. It is clear that against this backdrop, it is more important than ever for machine builders to distinguish themselves. But that is no longer possible with traditional hardware alone. They will also have to incorporate intelligence and services into their offerings, digitise their processes, pay attention to cybersecurity... And that's where the problem lies, because it requires different knowledge and expertise than they are used to,” explains Marc Vissers, Lenze's marketing and communications manager for EMEA West.

Pace of Automation

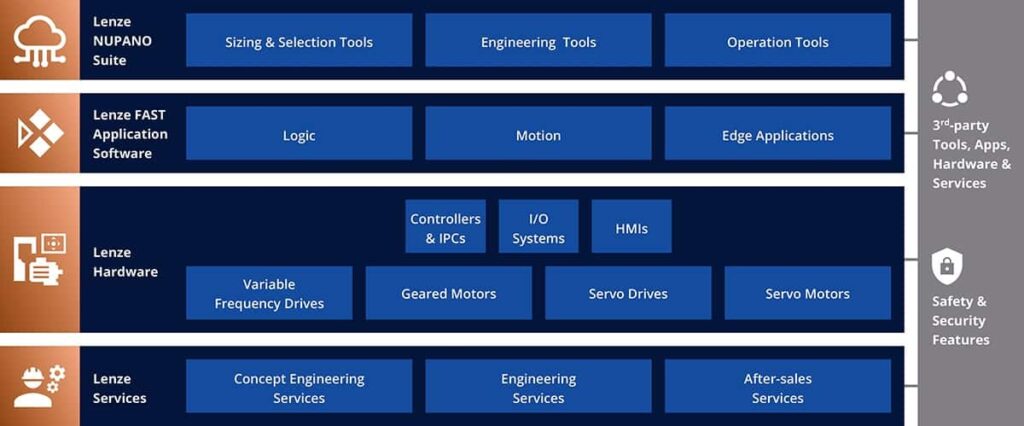

280 visitors to ‘The Pace of Automation’ in ’s-Hertogenbosch were able to experience the added value of working with Lenze. This was done broadly, covering topics such as cybersecurity, servitisation and web-based automation, and how machine builders can make use of them. But it was also done in depth, explaining how products such as the Nupano suite, the FAST application software and the new IE5 and IE7 motors can help in this regard. “Our entire portfolio is built on six principles that give machine builders a foothold in these VUCA times. At Lenze, we see openness, scalability, modularity, connectivity, safety and cybersecurity as the common thread in the design of our new portfolio, but also as the building blocks of tomorrow's machines.”

Winning strategy

Vissers explains what they mean by this at Lenze. “To make automation a winning strategy, you need domain knowledge. With our decades of experience, this starts with the drive train. With high-quality hardware components and intelligent software. To reduce the complexity of machine construction, the hardware we use is scalable. If more or less performance is required, you can easily choose a different controller without having to redesign the entire machine. We mainly use a modular approach with our software: machine builders simply select the modules that are relevant to them. Condition monitoring or OEE, for example, to get more out of your machines. Or ticketing for maintenance and repairs. And because we know that a machine never comes entirely from one supplier, all our solutions are open and can be seamlessly integrated with existing and future elements.”

Full service life of machine

This applies to everything Lenze does. From logic and motion in the field to edge applications and even IT for OT. The Nupano suite brings it all together to provide answers to megatrends such as energy efficiency, AI, the shortage of skilled workers, etc. throughout the entire life cycle of a machine. “This allows customers to significantly reduce the time they need for engineering, but also to generate new revenue from digital models and meet cybersecurity requirements. In short, everything that tomorrow's machines need to be. Our customers still have to build them, but we do everything we can to automate the automation as much as possible,” concludes Vissers.