Solutions for energy-efficient building automation

During the latest edition of Light + Building, Beckhoff Automation presented its building automation solutions across various technical systems. The focus was on future-proof technology for sustainable and energy-efficient buildings. Thanks to PC-based control, it is possible to bring all functionalities within a building together on a single platform and control them consistently using TwinCAT automation software, IoT functions and concepts for intelligent energy monitoring. A good example is the new MX System, which is a compact automation solution for air conditioning and ventilation systems that does not require a control cabinet.

Anyone involved in sustainability, CO2 savings and social responsibility must ask themselves the same question: How can I achieve a significant reduction in global energy consumption? The answer can be found in buildings. And it is no longer just an ecological answer; it is also increasingly becoming an economic issue. Only buildings that are optimised in terms of their energy consumption and that can monitor and measure energy appropriately and intervene autonomously are fit for the future. By connecting all technologies in a single building automation system, such as Beckhoff's PC-based control system, we can deliver on the promise of sustainable, energy-efficient construction and use. Everyone in the value chain benefits from this. Architects enjoy maximum creative freedom with optimal functional efficiency. Planners can draw up more reliable plans with reduced complexity. System integrators reap the benefits of simpler engineering and improved process reliability. Users can minimise operating and maintenance costs. And finally, investors get the best possible protection for their investment.

Configure everything instead of programming

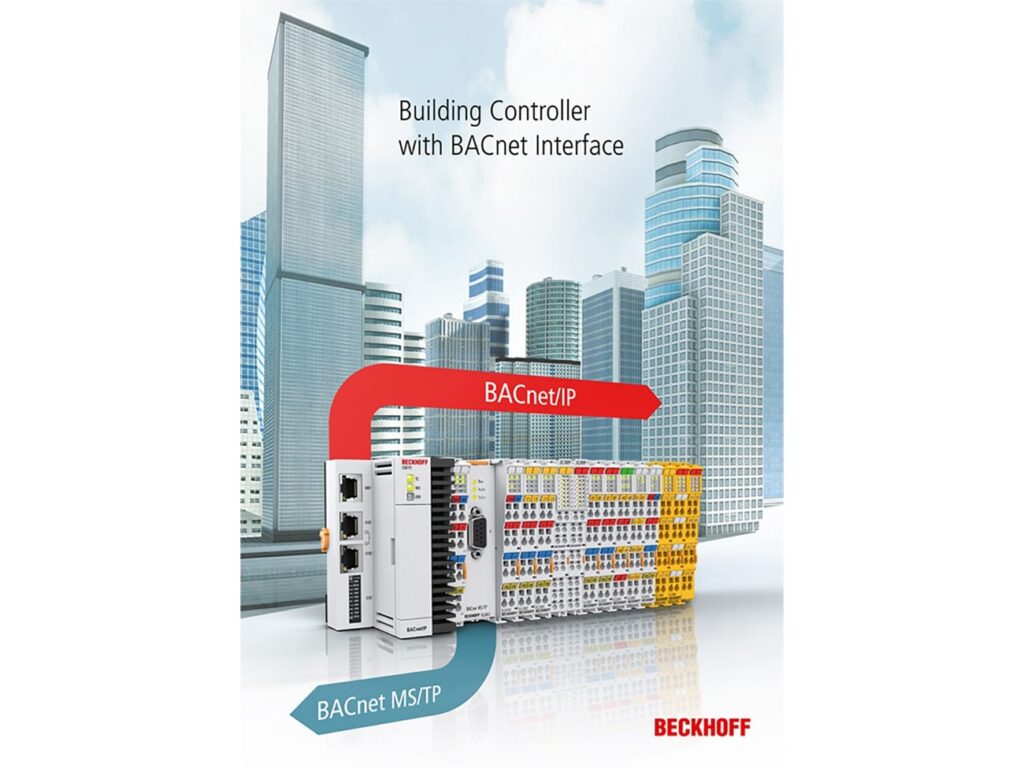

But what exactly can be achieved with TwinCAT software for building automation? One example is the TF8050 solution for lighting. The more extensive a lighting system becomes, the more the advantages of Beckhoff technology become apparent. For example, the use of decentralised bus connections in the network infrastructure significantly reduces cabling requirements. All lighting functions are supported in a single platform, such as remote control, importing and exporting Excel data, and simple maintenance measures. The TF8050 solution also includes functions for a Human Centric Lighting concept and DALI-2 sensors. Everything can be easily configured without the need for programming skills. Beckhoff also offers a BACnet solution, a standardised, manufacturer-independent communication protocol for building automation. This is used in HVAC, lighting control, and safety and fire detection technology. This protocol can be easily implemented with Beckhoff industrial PCs or embedded PCs, with full support for all services.

Ready for IoT

With the definitive breakthrough of digitalisation, IoT functions have also found their way into building automation. Anyone who wants to connect to the cloud can do so easily within TwinCAT. The focus is not so much on the pure implementation of protocols (such as TF6710), but rather on targeted communication with services in the cloud (such as the Microsoft Azure IoT hub or Amazon Web Services IoT). This happens in the background, making the communication connection much simpler and more native to implement than with a direct connection via the MQTT protocol. The user has access to these functionalities via PLC function blocks to easily send process data from the TwinCAT runtime to communication services in the cloud or to receive data from these services.

More compact hardware for greater flexibility

Beckhoff also offers innovative hardware technology to make life easier. Thanks to the launch of the MX System, switch cabinets are no longer necessary. The combination of the base plate and function modules can take over all the tasks and features of a switch cabinet: power supply, protection and distribution of fuses, generation and monitoring of auxiliary voltages, sequence control with inputs and outputs, control of motors and actuators, as well as the connection level for field devices. Users can configure the IPC, I/O, motion, relay and system modules that best suit their specific application. The certification of all components based on international standards means that MX-System can be standardised worldwide. It is a solution that greatly simplifies the efforts required for planning, assembling, installing and maintaining installations. In addition, the overall footprint of the system is smaller, while greater availability and flexibility are achieved. At every stage in the life cycle of a control system, MX-System offers enormous advantages over traditional control cabinets.