Harnessing the power of automation and digitisation in sign building

Rittal officially opened the doors of the Rittal Application Centre in Lokeren at the beginning of June. A new capstone to the philosophy it pursues together with sister company Eplan, but certainly not an end point. Together, they want to continue to move forward in the digital story and use combined solutions to automate the entire value chain in panel building, from engineering to maintenance. At the Rittal Application Centre, customers can not only see the technology at work, but also get a taste of what it all concretely delivers in practice in terms of quality, productivity and efficiency.

When Rittal launched its first standardised enclosure in 1961, the company headquartered in Herborn, Germany, had no idea what revolution it would spark. The team of developers had simply listened carefully to what panel builders needed. It would remain the common thread throughout its history. Koen Wolfcarius, managing director Rittal Belgium: “We not only expanded the range - three standard sizes became more than 30 in the meantime - but also thought about how to make our customers” jobs easier."

Addressing shortage of technical staff

The beginning of a story of automation and digitalisation. “Ever since 1989, we have been drawing the map of digitalisation in electrical engineering with sister company Eplan,” Wolfcarius points out. “The software back then is no longer comparable to what it is today. And neither is society anymore. A digital wave has swept over us and is also pointing the way forward. After all, it offers an answer to the shortage of technically skilled personnel facing manufacturing companies. We hear from our customers that finding the right people is often the biggest barrier to further growth.”

Value-added services

This is why Rittal already offered various services in its Modification Centre to support its customers. “In our workshop, we milled out the cut-outs they needed for customers. As a service, but in the meantime, forty of our Perforex machines are already at customers” premises in Belgium. The best proof that our solutions really help customers move forward." Thus, it evolved into a place for demos, training and even a place for building prototypes where physical twins come to life, so to speak.

With the opening of the Rittal Application Centre, this is now being followed up. “Because we want to bring even more added value to our customers,” says Wolfcarius. “How then? By starting to integrate the entire value chain. From engineering, through sourcing and manufacturing to operations.”

Integrated value chain for greater efficiency

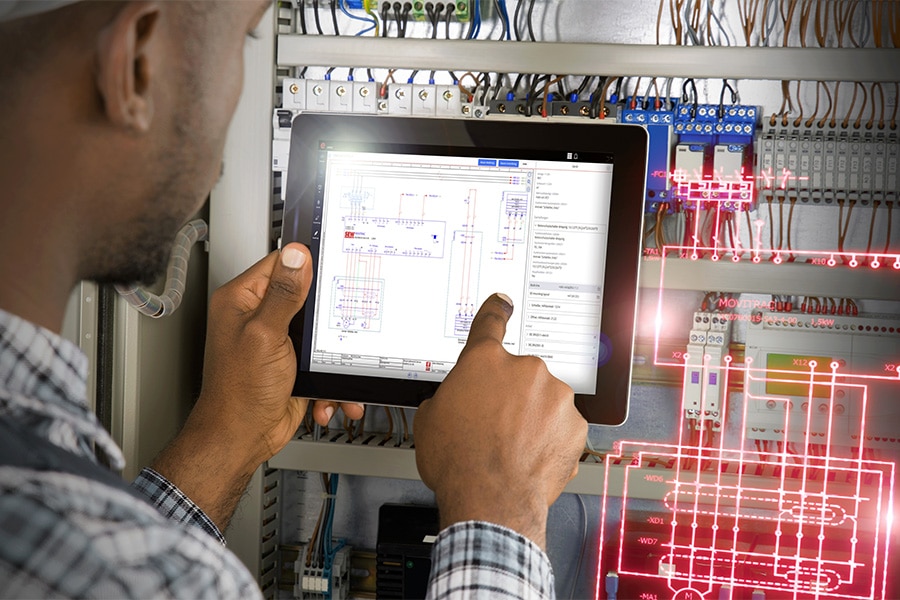

A story of synergy, because together with the simplicity and user-friendliness of sister company Eplan's engineering software, Rittal supports its sign building customers in each of the above-mentioned phases. Wolfcarius: “If we want to take the next steps in time savings and efficiency, we need to go back to engineering. By starting from a digital design, we create a digital twin and can optimise all subsequent steps. After all, from engineering we can then also control all machines directly and provide them with what they need in terms of products, operations and cabling without any chance of errors. In this way, we want to simplify the sign builder's work, so that a shorter training period is sufficient. Just click, read and screw on.”

Perforex and Secarex: win in time, save in errors

How this theory now concretely translates into practice became clear when walking through the Rittal Application Centre. Danny Forré acted as an able guide along the Perforex, Secarex and Wire Terminal technology. “Even a simple cabinet soon needs three to four openings. A manual job that easily takes two hours. The Perforex machine completes that job in about 15 minutes. Time that, incidentally, the operator can also usefully fill, as he does not have to stand by the machine.”

The next step is cutting cable trays and DIN rails to size. Rittal puts forward its Secarex machine for this purpose. “A semi-automatic solution. You only have to place the cable tray against the stop, the machine does the rest. With two starting points: accuracy, so that the mounting holes are perfectly positioned, and as little material loss as possible.”

World first with Wire Terminal

In that same small cabinet that served as an example for the Perforex, of course, the necessary threads belong. 84, to be precise. The Wire Terminal also extracts all the information about these from the Eplan Pro Panel software, so that they are perfectly cut to size, identified and finished as the customer wishes. “The bundles are delivered in the right order. Whereas the operator used to have to measure everything himself, he now only has to follow the plan digitally and make the right connection. In other words, assembly instead of cabling. Child's play,” says Forré.

By the way, with the addition of the Wire Terminal to its Application Centre, Rittal Belgium is signing up for a world first. Colleagues from its headquarters in Germany were therefore present at the opening and are looking forward to seeing how this addition goes down.

Also for small series and single pieces

With this opening, Rittal wants to show that automation and digitisation pay off even for smaller series or single pieces. Forré: “The time invested in the digital engineering of your enclosure is never wasted. The resulting detailed 3D image makes the assembly of enclosures much more intuitive and reduces the risk of errors right from the start. Time is also saved because the different steps do not have to follow each other, everything can be done in parallel. When you only have one cabinet to build, it is just as important that it is done right the first time in the shortest possible time. Customers can therefore increase their efficiency by using the Rittal Application Center, without having to invest in these machines themselves. After all, this workshop remains first and foremost a production area.”

Staying attentive to needs

And although the circle seems complete with all these machines, Rittal continues to look ahead. “Not every customer is as far along in this story of integration. Nor will it apply to every customer. Therefore, all this technology may as well serve perfectly stand-alone. So we still have a long way to go to achieve an integrated value chain. 75% of that work is still ahead of us. But at the same time, we are keeping our eyes and ears open for new technological developments. Apple just launched its VR glasses. Are there opportunities there to help sign makers move forward? Time will tell, but we remain attentive and alert to our customers” needs and questions. As we always have," concludes Wolfcarius.■