Motion control at its best

Getting the industry moving. That's what Siemens' hardware and software solutions do. At the past edition of Indumation, Siemens' Best Application Contest awarded some great examples of how its motion control and drive technologies provide clear added value in practice. The online voting campaign turned out to be a neck-and-neck race until the last moment. Therefore, we are happy to introduce the stage to you.

Even today, in a digital world, the drive system still appears to be the starting point when building machines. “Motion control is all about the controlled movement of an object, and that requires a synchronised interplay of a lot of hardware components,” says Bart Laplasse, Head of Motion Control at Siemens Digital Industries. “With the devices we market, we also want to assist users to bring out all the interesting data present in a drive train easily and efficiently. From there, we can help our customers build solutions that turn this data into valuable information. To optimise production processes or to develop new business models. This is a first important pillar of digitalisation that focuses on the operational machine.”

“A second key pillar is to build the new machine as efficiently as possible. This means simulating as much as possible in the concept/design and engineering phases, so that lead times are reduced and the chance of anomalies after the machine is built is reduced to zero.” How customers combine Siemens' motion control and drive technology portfolio with their own innovative strength and creativity is the basis of the Best Application Contest.

First place: Catael and Engima

Cutting cheese cubes is not without its challenges. Cheese is a natural product, which means that no two cheese balls are ever perfectly the same. When a customer wanted to optimise its existing slicing machines, machine builder Engima turned to engineering firm Catael. The goal? To improve product quality, switch faster between different types of cheese, drastically reduce waste per product, and shorten cycle times.

“It soon became clear that a new machine concept was needed to meet the customer's requirements. Engima set that up, we were in charge of steering,” says Bart Claeys of Catael. Servo technology was an obvious choice, because of the required dynamics. Sinamics S120 turned out to meet the specifications perfectly. “Siemens is a fixture for us. Here we made smart use of the simulation possibilities in TIA Portal V16, so we didn't have to build a simulation environment ourselves, but we could prepare and test everything even before the hardware arrived.”

What did remain to be done was fine-tuning. “With more efficient cutting patterns and optimised motion profiles, we were able to tick off everything on the customer's wish list. Smooth production changes, shorter processing time (20%) and less waste (10%). The fact that he has already placed an order for a second one is the best proof that we succeeded in our mission.”

Second place: CDC Automation

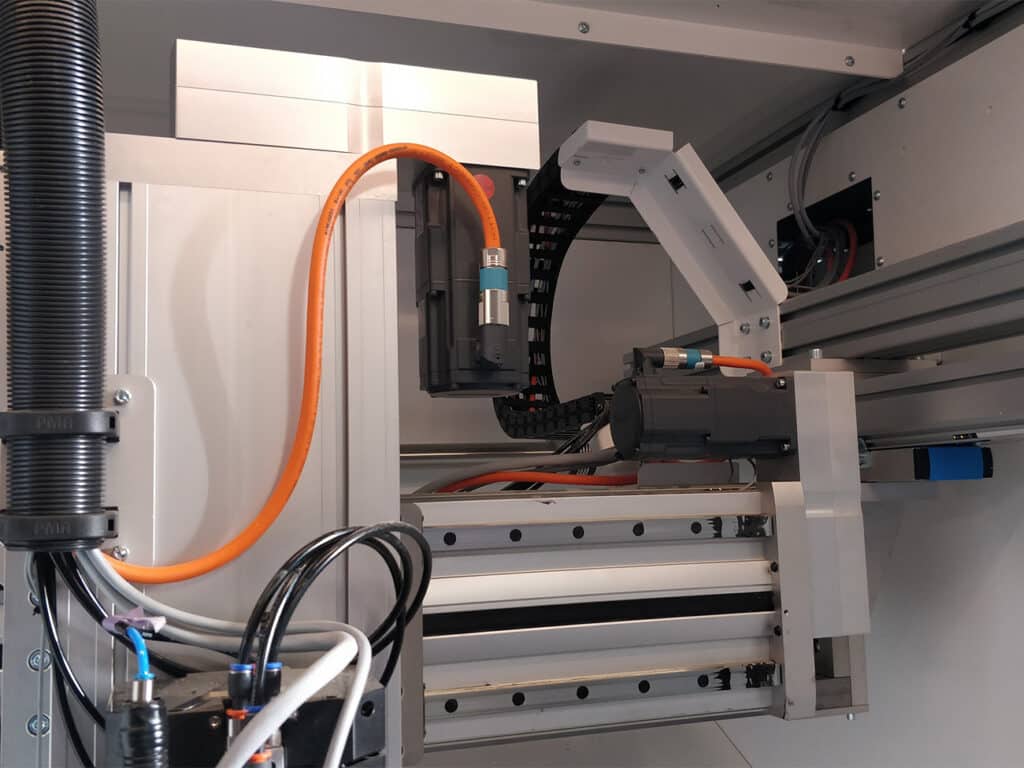

Third Best Application Contest entry, third podium finish. The public clearly knows how to savour CDC Automation's flight forward. One of their recent achievements is a fully digitally designed three-axis milling machine.

“We constantly want to integrate new technologies. To help our customers advance and also to present our employees with new challenges all the time. For us, this project was a first introduction to digital twin technology,” says managing director Christofe De Craene. “We first designed the machine completely digitally using Siemens NX drawings and were therefore able to identify a number of errors in the machine design. For example, the tool change was not perfectly positioned. In addition, we could already programme and simulate everything in parallel with the mechanical process. That resulted in a significantly shorter time to market.”

For CDC Automatisation, the intention is now to integrate this way of working as standard in all machine building projects and to assist other parties in creating digital twins. “In our opinion, this really is the way of the future and we could count on support from Siemens throughout the process to get to grips with this way of working.”

Third place: Vermeire

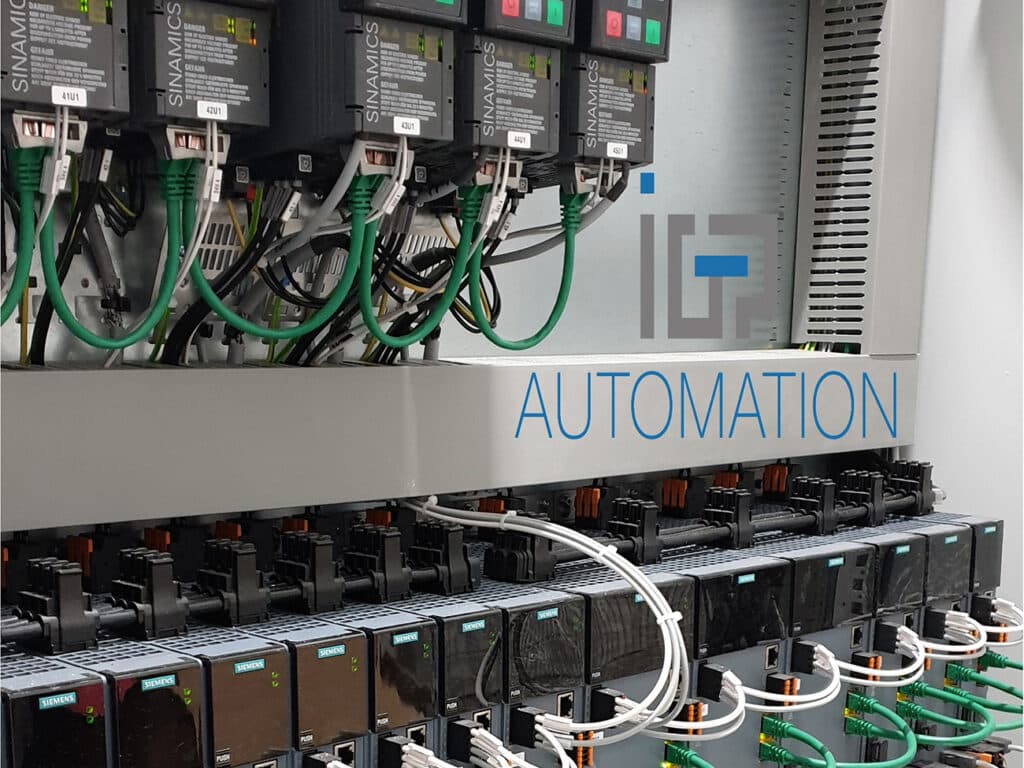

In a few months - and in the middle of the pandemic - Peps Engineering, IGP Automation and Vermeire managed to start up a new, 100% automated production line for PVC pipes.

“The company produces wastewater treatment tanks for residential buildings. The PVC pipes are used as supply and discharge for wastewater. The investment in this cutting machine made it possible to take over production from a subcontractor,” says Grégory Bragard, Area Sales Manager at Vermeire. The PVC pipes are available in a wide range of diameters and lengths, and thus also in different masses and sizes. No fewer than thirteen Sinamics S210 servo drive systems, controlled by a Simatic S7-1500T automaton, are required to fully automate conveying, cutting and sorting, and this regardless of the dimensions to be produced.

“One of the biggest strengths of the Sinamics S210 servo drive system is that there is only one cable for power and control. Add to this the greater compactness of the motors for the same power, and you get much more flexibility and options in design. Configuring the system via TIA Portal also delivers a lot in terms of ergonomics and standardisation.”

You can read these and all the other entries for the Siemens Best Application Contest 2022 in detail at www.siemens.be/best-

application-contest