Logistics sector embraces new technology

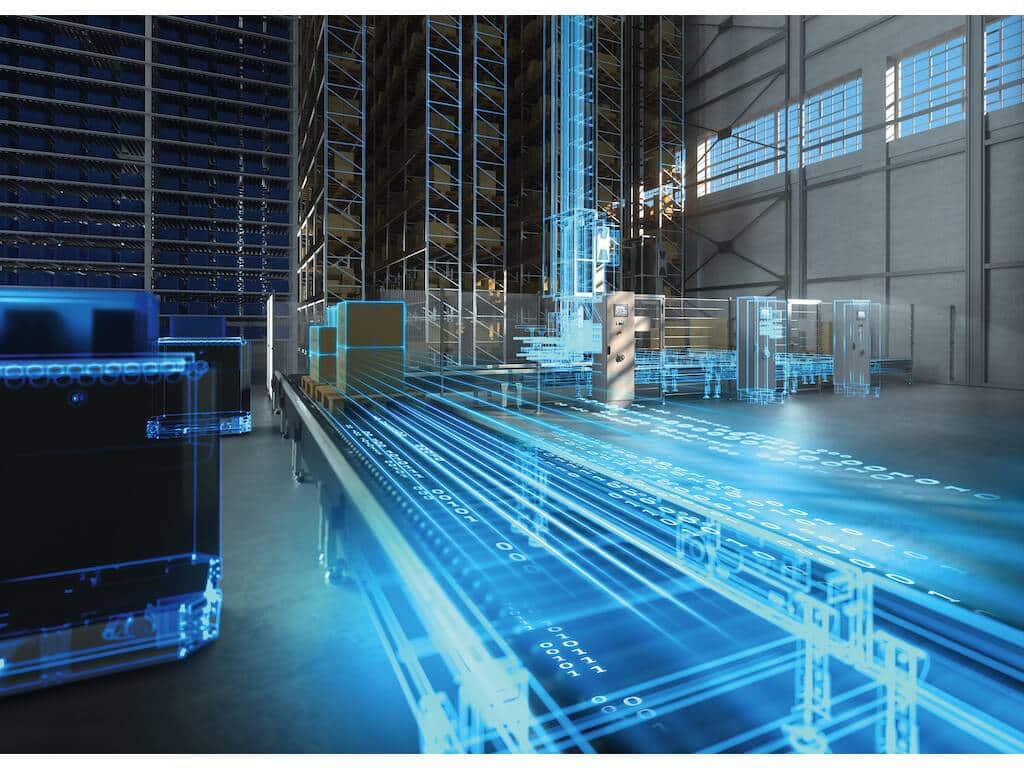

Do you know how smoothly your goods move flexibly through your production and warehouse(s)? Increasingly, companies' competitiveness will depend on the extent to which they can serve their customers quickly, accurately and in a personalised way. So anyone who wants to make work of their e-commerce offering will need to have their logistics and intralogistics processes completely mastered. But even those who do not have a webshop will benefit from taking a close look at their goods and data flows. Because new technologies can provide a completely new kick.

Everyone who produces has to deal with (intralogistics). Whereas logistics includes the transport of goods, for example, along the entire value chain from producer to end user, intralogistics deals specifically with the flow of goods and information within the operating walls of a site. In other words, in and around production, to and from and in the warehouse with the aim of constantly optimising them. “An area for which many companies - including SMEs - still have a lot of potential is mastering the art of organising these intralogistics processes as efficiently and flexibly as possible in a context that is changing ever faster ”, cites Siemens Digital Industries Strategy Manager Jurgen De Wever. “Consumers today want products with a personal touch. Something that naturally also trickles down to typical B2B environments such as industry, even down to the level of single pieces. As a result, manufacturers want to respond more and faster to changing requirements. Not only machine cells and production lines then have to be a lot more flexible, but also the logistics apparatus around them. In addition, we have become accustomed and spoilt to ‘instant’ delivery times. Ideally, we would like to have our products delivered tomorrow, with a track-and-trace code to follow everything up.”

Accelerating automation and digitisation

Quality, flexibility, availability, high throughput and transparency are the keywords in modern logistics installations. So it should come as no surprise that we see more and more robots, cobots, AGVs, autonomous forklifts, multifunctional conveyors ... popping up combined in this domain. De Wever: “The (intra-)logistics sector has fully embraced automation and digitalisation in recent years. Large industrial players from, say, the food or automotive industry, but also typical e-commerce companies, are usually at the forefront here. This way, innovation cycles can be completed quickly, gain application maturity and become affordable. Think of how simulations based on digital twins can help to quickly find the right combination of, say, conveyors, robotised palletisers and AGVs to achieve a certain logistics performance inside an existing building. Or how application-specific IoT structures and algorithms can help prevent unplanned downtime. Because when a link in the (intra-)logistics chain fails, it can have huge consequences for the entire supply chain. ”Cutting edge technologies such as blockchain and 5G will also soon be adopted here. That has everything to do with the added value they have to offer in these processes.

Systems approach

Siemens therefore resolutely takes a systems approach. “These rely on application-optimised hardware and software in the field of automation and drive technology that you also find in the rest of production. “We are talking here about the Simatic automation portfolio, the engineering framework TIA Portal, Sinamics frequency inverter s and Simotics servomotors. We achieve distinctiveness and added value with our digital offering under the form of software platforms and features that we apply at different levels. From the design phase, through the simulation phase, right up to engineering. We do commissioning mainly virtually, then in reality: quickly and accurately. Further management and optimisation are also covered. The degree of integration and speed increases particularly here. All this in a technological framework that remains recognisable to the existing engineering and maintenance teams,” explains De Wever.

Expertise in (intra-)logistics

Siemens couples its broad portfolio with in-depth application knowledge in intralogistics. “We get these competences from the intralogistics experience we have accumulated over the years in the many in-house productions and the intense cooperation with partners in this field, often machine builders and system integrators. Being able to realistically assess and apply the cross-fertilisation between this application knowledge, industry-specific know-how and applicability of digitised automation is essential. It enables our customers to move quickly to value creation that has a direct impact on their competitiveness. It is quite exciting to see how new technologies are further accelerating change in the (intra-)logistics world,” De Wever concludes.