Towards a more flexible and sustainable industry

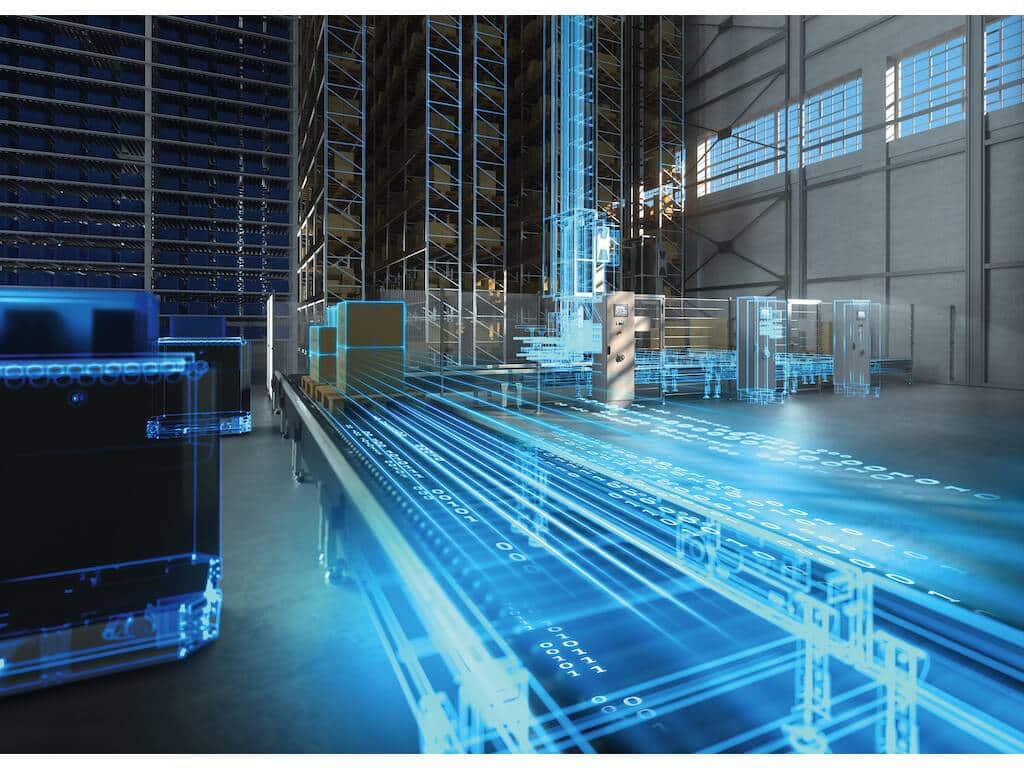

Because to cope with the aftermath of the corona pandemic, the growing demand for individualised products and the need for more sustainability, we will have to find solace in digitalisation and automation. Siemens brings all data together in a continuous cycle that connects the virtual and real worlds. Out with silos, on to a better understanding and use of data.

“In recent years, more and more data became available at a rapid pace. This makes it clear that digitisation does not work with an end line. Rather, it is the beginning of a never-ending loop. Companies capture data, learn from it and take the next step,” explains Cedrik Neike, member of the Siemens board of directors and CEO of Siemens Digital Industries. “In manufacturing, this makes available an infinite source of knowledge that we do not yet fully exploit. Everyone who produces can make use of that potential though, both production sites with a rich history and completely new ones where the first pixel has yet to be planned.” With its Digital Enterprise portfolio, Siemens supports customers in this area. Thanks to digital twins and the use of future technologies such as artificial intelligence, customers can respond quickly and flexibly to global challenges.

Fast and reliable connections

The basic principle is simple. Siemens links all data from the entire life cycle of products, production systems and information technology with data analysis and classic control technology and connects the production level with the office. This creates a continuous cycle of optimisation. In this industrial Internet of Things, industrial processes are modular and flexible, allowing optimal adaptation of all parameters throughout the entire life cycle. And this even extends to factory buildings and the workflow of suppliers and logistics partners. The prerequisite, however, is that data gets to the right place quickly and reliably so that appropriate responses can be made. Siemens therefore continues to help push the boundaries of state-of-the-art technology such as industrial 5G communication networks. With such private networks, companies will be able to tailor them specifically to their performance, reliability and security requirements. Siemens showed a prototype of an industrial 5G campus network in one of the exhibition halls. In the future, these will be used during trade fairs for experiments and field tests.

To the edge and the cloud

Interesting to cite here is also Industrial Edge. This concept allows Siemens customers to flexibly exploit the benefits of data processing through edge or cloud (depending on the application).

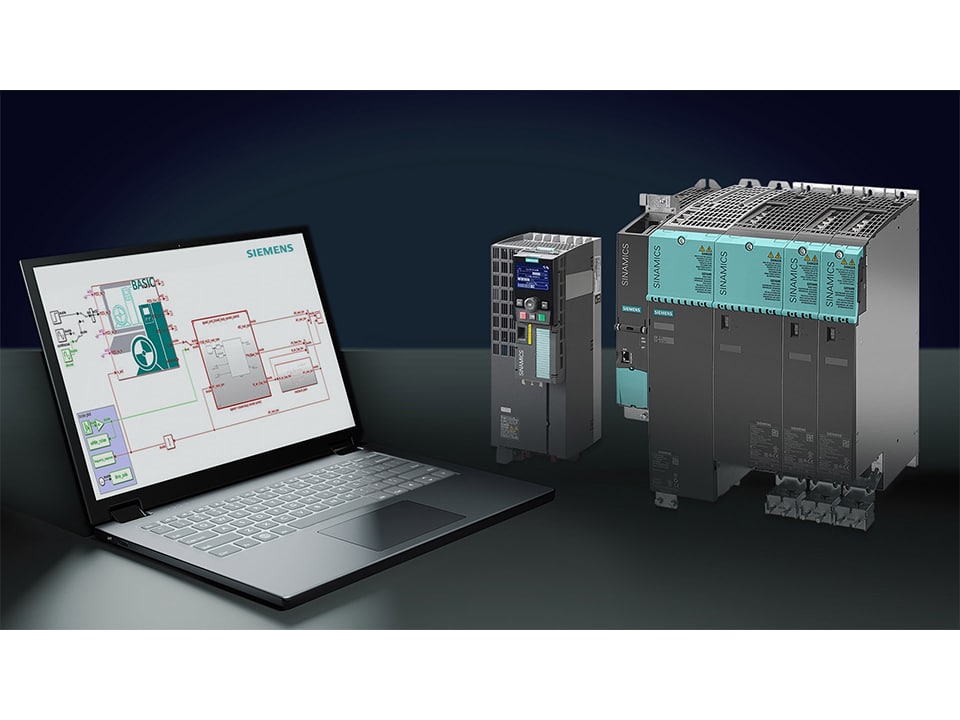

Siemens is also expanding its offering in edge computing to include real-time data analytics in manufacturing and how it can be intelligently applied. On top of connecting Simatic and Sinumerik

controllers with the Siemens Industrial Edge platform, the offering for connecting drive technology has also expanded. After all, drive technology provides a good indication of machine availability. In addition to data on variables such as speed and torque, the drive also provides information that can typically serve edge computing. This gives users a tool to operate their machines without errors and optimally within their parameters (e.g. energy consumption). Intelligent analysis technology can inform operators at an early stage whether maintenance work is needed and whether energy can be saved.