First applications of the digital twin

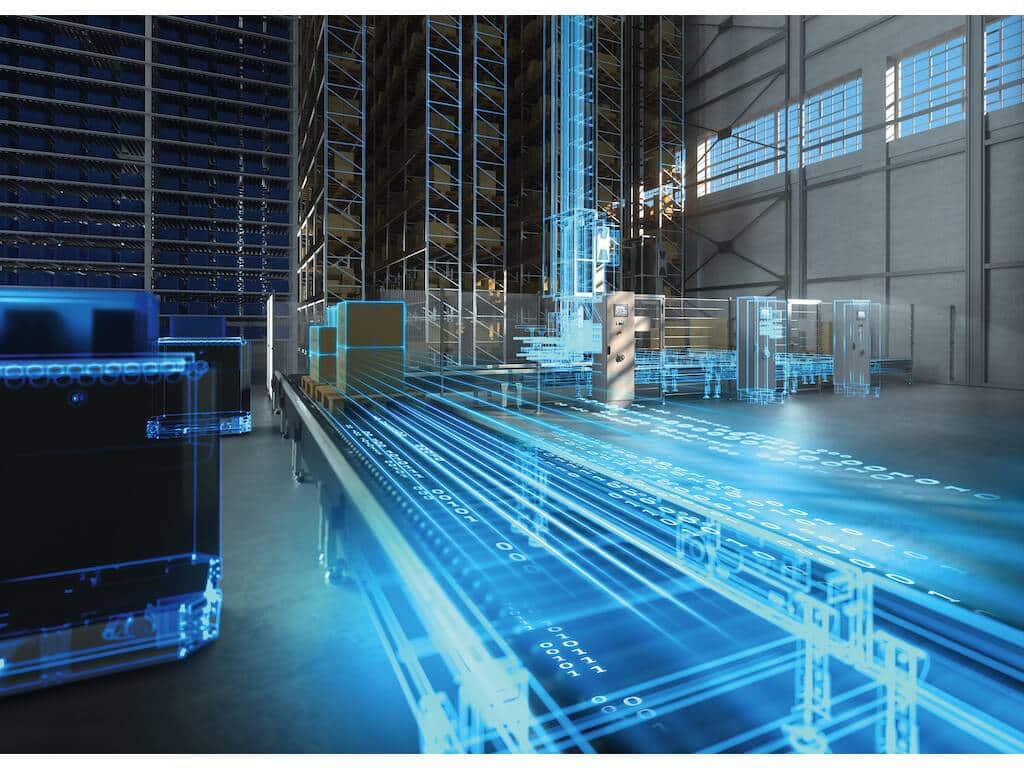

In the future, the digital twin will be as natural as providing datasheets on the website now. Lenze showed at the last Hannover Messe Digital that digital twins are already more than mere theoretical concepts and are finding their way into today's industrial practice.

Lenze has been researching the digital twin for several years. The company headquartered in Hamelin, Germany, is now also taking further steps in the application. Developers and designers can use a web service, the EASY System designer, to create an initial digital image of a machine. Further web services then enrich this structure directly with technical data and documentation of the equipment used. The resulting digital twin creates a new standardised and automated consistency of data and information, and forms the basis for use in further tools and applications. And these are just the first steps. “Moving to the concrete implementation, we are going to make asset data of our system components, such as the digital nameplate, technical data and documentation, available via web services. This may not sound very exciting at first, but the added value over the entire life cycle of a system is enormous, as this data is passed on from engineering to commissioning to maintenance,” explains Patrick Bruder. He works as Business Development Manager Automation at Lenze.

Common database

Provision of component data by the supplier simplifies integration processes in the development project. The aim is to bring products to market faster and more cost-effectively by avoiding duplicate modelling and, ideally, completely hardware-free development. Lenze's automation specialists want to move away from the pure visualisation of a product. A digital twin is the complete digital representation of a machine or system in all its aspects. It is not necessarily a specific file or model, but rather a framework around all the versioned and referenced data of a product. In this way, all tools can work on a common data stem during the product's life cycle, which is successively supplemented by further information.

About Lenze

Lenze is a leading automation company for machine builders and a specialist in motion centric automation. As a systems provider with solution competence, Lenze works for and with its customers to create mechatronic products and packages of the highest quality. They are powerful systems that combine hardware and software for machine automation, together with digitisation services in big data management cloud and mobile solutions and software for IoT. Lenze employs more than 3,700 people worldwide and is represented in more than 60 countries. Lenze's growth strategy is to continue to invest heavily in Industry 4.0 domains in the coming years.