Pneumatics at its most sustainable

Sustainability must become the foundation of a competitive European industry. Because if we want to achieve the ambition of carbon neutrality, we will have to move up a gear. At its annual press conference, Festo therefore placed the topic right at the top of the agenda. From its own products getting a makeover to make them more sustainable, to Festo Energy Saving Services to help companies save energy, to the development of a bioreactor that can efficiently produce algae on a large scale using photosynthesis. The company also announced that it will be carbon neutral by early 2023.

Automation will play a key role in the industrial transformation towards climate protection, resource efficiency, sustainability and the circular economy. Festo also wants to set an example itself by drastically reducing its carbon footprint over the next two years.

“As a result, all our production and logistics sites worldwide, as well as the German sales sites and headquarters in Esslingen, will be carbon-neutral from the beginning of 2023,” explained CEO Oliver Jung.

Festo has used the United Nations Sustainable Development Goals as benchmarks for its own sustainability strategy. It visualises its efforts in the so-called Blue World concept. “With this, we want to show how automation technology can balance the growth of the world's population on the one hand and the protection of our natural resources and climate-neutral production on the other,” Jung explains. The aim is to help transform industry into efficient and climate-friendly production.

Partner for customers

“Our customers see us as a partner in their own transition. Together with us, they can shape the transformation of the industry. Innovations will play a key role in this,” Jung adds.

Festo has its letters of honour ready in this respect. Digital and intelligent pneumatics, automation platforms and concepts to save energy in pneumatics... Festo also presented the world's first pneumatic cobot at the last Hannover Messe. A pioneering role it intends to continue to take up, by the way. In 2021, 7% of its realised sales flowed back to research and development.

To meet the challenges of today and tomorrow in that transition, companies can count on Festo Didactic. Training that provides learning content and learning environments to teach new subjects, based on what is needed in the fields of IT, artificial intelligence, data science and sustainability.

Sustainable products

Carbon neutrality starts with sustainable products. Festo's ‘Stars in Automation’ are more than 2,200 pneumatic and electrical components that belong to the core range of the German automation specialist. Machine builders can use them to build some 80% of all their applications easily, quickly (even in large quantities) and at an interesting price. The outstanding feature of the latest additions to this range is durability. They are developed to save weight, volume, energy, raw materials and space, the building blocks to achieve more sustainable machines.

A good example is the new round DSNU-S cylinder, which offers the same performance as the already proven DSNU cylinder, but is 35 mm shorter and has a 40% closer mounting interface. This involves close cooperation between developers and production planners to reduce cycle times.

Sustainable engineering

But how do you know if you are making the sustainable choice to build your machine? The design of a machine lays the foundation for its carbon footprint. By providing free engineering tools, customers can get an idea of which products are associated with which CO2 emissions. It also pushes for innovative solutions to then bring those emissions down.

Julia Bikidis, project manager CO2 reduction for the product portfolio at Festo: “The focus is always on how the customer uses our products. But we also look at how much CO2 was needed to make them. We expect a digital product passport to become the standard in the next five to 10 years. With our efforts related to digital twins based on the administration shell, we are trying to anticipate this and achieve a carbon-neutral product portfolio. The main support in this will come from the technological advantages offered by Controlled Pneumatics,” Bikidis stressed.

Controlled Pneumatics

For those who now hear it thundering in Cologne: by Controlled Pneumatics, Festo means mechatronic pneumatic systems with innovative valve and communication technology on board. Based on the variables picked up by sensors, digital control can be exercised. In this way, users can still enjoy the simplicity of standard pneumatics to get things moving, but at the same time gain more control for more reliable, precise and efficient solutions.

The textbook example of Controlled Pneumatics is the Festo Motion Terminal VTEM, with which Festo digitised the world of pneumatics. Festo takes compressed air technology to a whole new technological level, where saving resources, energy efficiency and sustainability are the code words.

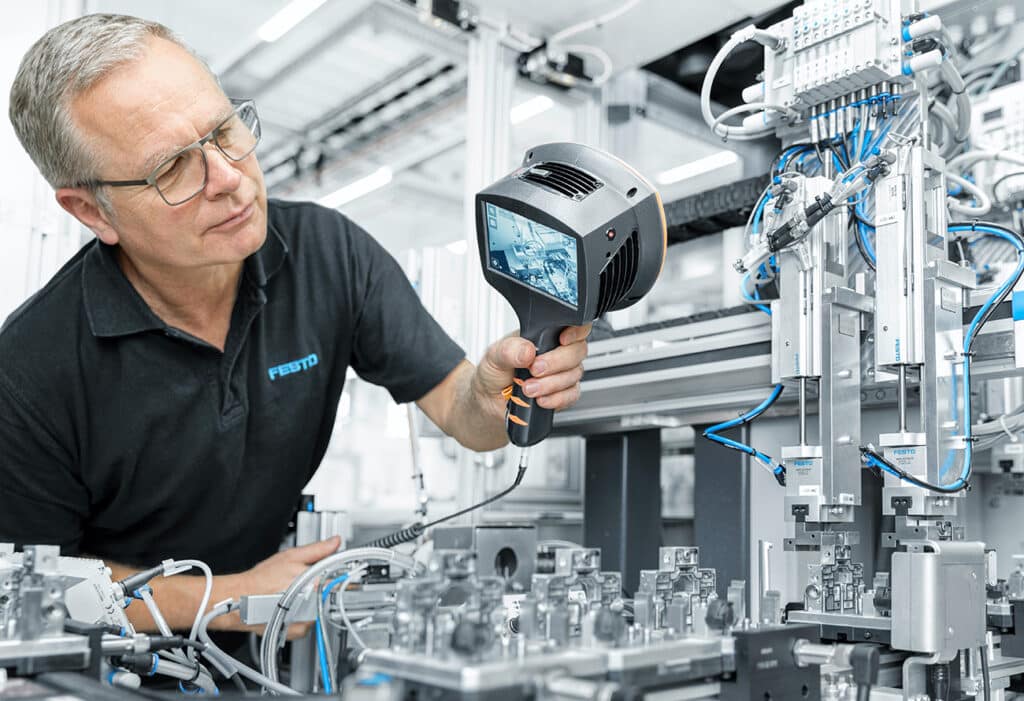

In search of compressed air leaks

A good idea, especially given current energy prices. That the Festo Energy Saving Services offer is also highlighted against this background should therefore come as no surprise. Festo opts for an approach according to DIN EN ISO 11011 and looks for possible savings in how compressed air is used in a standardised manner together with its customers - by the way, did you know that artificial intelligence can also show the way to energy gains?

The experts go through five steps. During the first three, they scrutinise the production, pre-treatment and distribution of compressed air. Then they turn their attention to the consumers: pneumatic applications and systems. In the last step, a monitoring system is presented to permanently monitor the energy status. Festo AX Predictive Energy, for example, creates a fingerprint of your production line and constantly puts it against the current status. Using machine learning and artificial intelligence, leaks can thus be detected automatically.

Automated biomass accretion

Algae are the little heroes of the climate. Even in their natural state, they are extremely efficient photosynthesisers that absorb ten times more CO2 than plants on land. In bioreactors equipped with the necessary sensors, control technology and automation, the efficiency of algae can be increased even further, up to 100 times the level of land plants. This shows their unique potential to achieve a climate-neutral circular economy. With the PhotoBionicCell research project, Festo is demonstrating what a possible approach to industrial biologisation could look like.