Siemens takes industrial production to the next level

In doing so, it aims to help companies in the production and process industry to respond to rapidly changing market conditions and circumstances. Siemens makes production more intelligent and therefore much more flexible-thus taking the industry to the next level. To do so, the company combines automation and digitalisation solutions with pioneering technologies such as artificial intelligence, edge and cloud computing or additive manufacturing. Via this link https://sie.ag/2TIM1AO interested parties can register for the virtual event “Digital Enterprise SPS Dialog” on 26 November 2020, discover the different topics in a virtual 3D showroom and learn more by engaging in dialogue with experts. The new products include a ready-to-use open Industrial Edge platform, new edge hardware and a new edge application for drives. A new decentralised drive system will also be launched. Besides a solution for non-vendor programming of robots in the Totally Integrated Automation (TIA) portal, other novelties this year include the innovative Cloud Connect products for integrated data access and new Connectivity and Remote Collaboration Services.

Using cloud and edge technologies, manufacturing processes can be digitised, allowing companies to work more flexibly and efficiently. With Siemens Industrial Edge, an open software platform for implementing machine-level IIoT solutions, more applications can be introduced to the shop floor in a shorter time to further increase machine and plant productivity while reducing implementation and operating costs. This is why Siemens is now introducing the Industrial Edge Management System, a central and enterprise-wide scalable infrastructure for managing connected edge devices and apps. Combined with the hardware and software products already in place, this open platform Industrial Edge V1.0 offers users a ready-to-use, seamless solution. In terms of hardware, there are also a number of additions to the Industrial Edge portfolio. The Simatic IPC227G industrial PC with the latest processor technology is available as a nanobox and panel PC. Its excellent performance and numerous interfaces make it the ideal platform for Industrial Edge and Artificial Intelligence (AI) applications.

In the field of drive technology, Siemens expanded its Analyze MyDrives MindSphere app with a corresponding editors version. In doing so, the company introduces the first edge application for drive technology on the market and demonstrates how edge and cloud computing can be intelligently linked. On the Predictive Services for Drive Systems front, the MindSphere-based service application gets an intelligent update. In the latest version, the Predictive Service Assistance app is based on an AI algorithm. The app supports customers who want to increase the availability of monitored assets and optimise maintenance efficiency. The Sinamics G115D is a new decentralised drive system developed specifically for use in horizontal conveyor applications. Sinamics G115D is a complete drive system with motor, frequency converter and drive in one device.

Regularly changing product variants and external conditions require more flexible machines, and the level of automation is also increasing through the use of processing and assembly systems. This is supported by the integration of robotics into production machines. With the Simatic Robot Library for the Simatic Robot Integrator, Siemens presents a new universal robot library for the TIA (Totally Integrated Automation) portal. Using the Simatic Robot Library, users will in future be able to programme the majority of robots from any manufacturer on the market in the TIA portal. They will be able to use standard control concepts based on the Simatic Robot Integrator and Simatic HMI. With the standard environment of the TIA portal, users will save up to 30 per cent time when engineering new total systems, thus reducing time-to-market.

Siemens presents innovative Cloud Connect products that guarantee continuous data access via all interfaces and provide standards as a basis for current and future IIoT applications. With the fully web-based Simatic PCS neo process control system, customers have a secure internet connection and direct system access at any time and with any device. In addition, Siemens also highlights the advantages of the Power-over-Ethernet portfolio as an essential part of digitalisation in modern companies. There is increasing demand for components that can be installed and operated quickly and without complicated wiring at the desired locations. All new PoE switches are based on the latest IEEE 802.3bt standard. With the Module Type Package (MTP), Siemens presents a solution for plant operators who want to expand their production quickly and flexibly or switch to a new product.

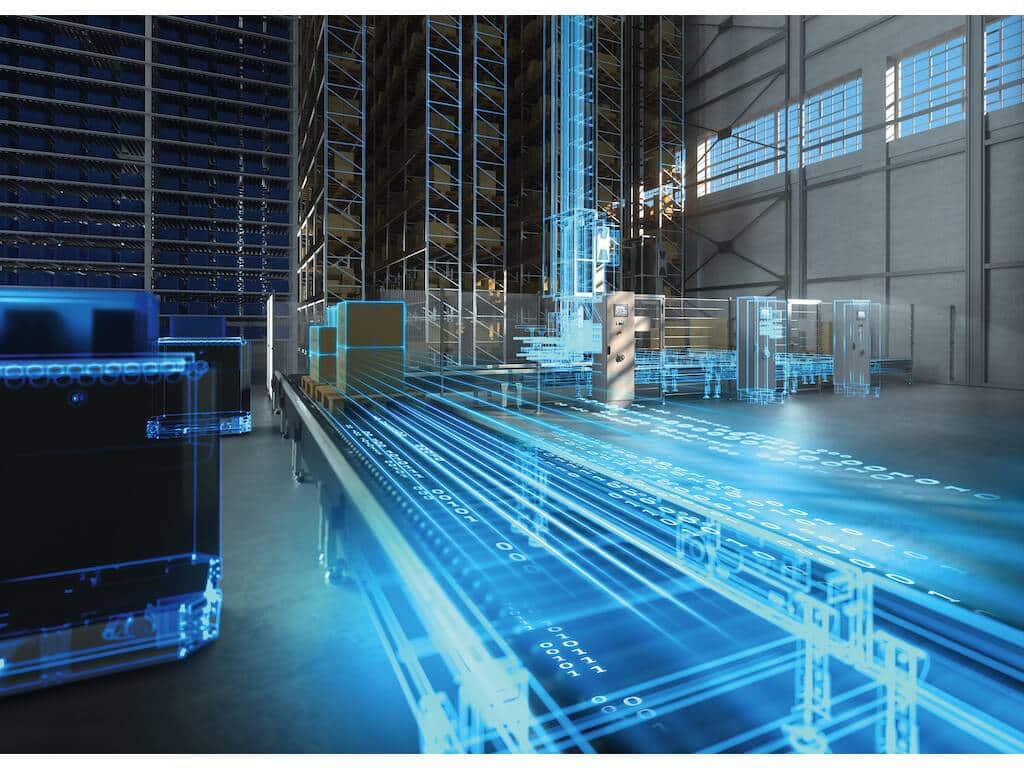

In its Siemens Digital Enterprise Services division, the company is introducing a new range of services. Digital Factory Optimisation simulates and optimises production and logistics environments through artificial intelligence. Virtual Commissioning Services make it easier to get started with virtual commissioning. In doing so, Siemens experts structure, implement and maintain the digital twins of production lines, machines and plants. Moreover, new Connectivity Services allow users to connect the production network from any type of data source to any type of higher-level information system, be it Edge, SCADA, MES, ERP or the cloud. New Remote Collaboration Services enable fast and comprehensive engineering, as well as remote fault diagnosis and troubleshooting.